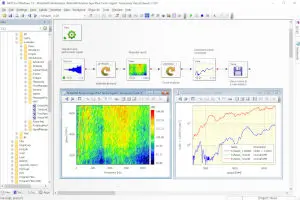

Understanding CAN bus (Controller Area Network Bus) is essential to modern automotive engineering. The CAN bus, and its variants, are now universal across the automotive industry and beyond. On many vehicles, thousands of parameters are available and are transmitted around the vehicle. In addition to being vital to correct vehicle operation, this information is invaluable to qualify data gathered during automotive testing. This requirement is what created the need for CAN bus logging to be integrated into measurement systems like Prosig’s DATS-solo and DATS-tetrad hardware.

Why Is CAN Bus Important for Acoustic & Vibration Measurement?

Since this is the Noise & Vibration Measurement Blog, it is useful to understand CAN bus logging and why it is often essential to noise & vibration measurement. There are several reasons:

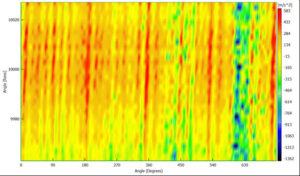

Data Collection: CAN bus logging enables engineers to collect and record vast data from various sensors and systems within a vehicle or application. This data can include parameters related to noise, vibration, and harshness (NVH) and information about engine performance, transmission, suspension, and other subsystems. By collecting this data, engineers can analyze it to identify issues, optimize performance, and improve overall system efficiency.

Real-Time Monitoring: CAN bus logging allows engineers to monitor the data in real time, enabling them to observe the effects of changes in the system or to identify issues as they occur. This real-time monitoring is crucial for noise and vibration measurement tasks, as it helps engineers understand the relationships between different subsystems and their contributions to NVH characteristics.

Time Synchronization: When collecting data from multiple sensors and systems, it is crucial to have accurate time synchronization to ensure that the data is correctly aligned and can be meaningfully compared. CAN bus logging systems typically provide precise time-stamping of the recorded data, allowing engineers to accurately analyze the relationships between different parameters and events.

Correlation Analysis: By logging data from various systems on the CAN bus, engineers can perform correlation analysis to identify the root causes of issues like noise, vibration, and harshness. This analysis can help pinpoint the specific components or subsystems responsible for undesirable NVH characteristics, leading to targeted improvements and optimizations.

Simplified Troubleshooting: CAN bus logging allows engineers to capture data from multiple systems and sensors simultaneously, which can significantly simplify troubleshooting efforts. For instance, if a vibration issue is detected, engineers can analyze the logged data to determine if the problem is related to the engine, transmission, suspension, or other systems, narrowing down the potential causes and enabling more efficient problem-solving.

Advertisement

COMPLEXITY MADE SIMPLE

From sensors to DAQ to analysis & reporting, Prosig supports your entire measurement chain

Whether you need accelerometers from our colleagues at DJB Instruments, microphones, pressure sensors or something else, Prosig can supply them as part of your system. Or you can use your own. Discover more about the Prosig hardware and software range.

In summary, CAN bus logging plays a vital role in R&D and test & measurement tasks like noise and vibration measurement. It allows engineers to collect, monitor, and analyze data from various systems and sensors, enabling them to optimize performance, troubleshoot issues, and validate the performance of new designs and updates.

What is CAN Bus and How Does It Work?

The CAN bus (Controller Area Network) is a communication system used in vehicles and other industries to allow different electronic devices or components to communicate with each other. Think of it as a “language” that these devices use to “talk” to one another. Here’s a simple explanation of how it works:

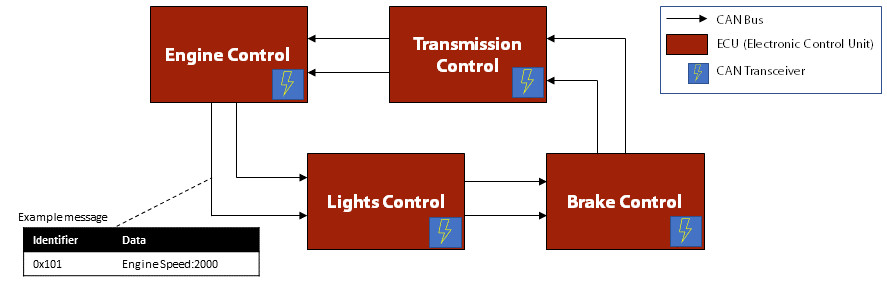

Electronic devices: In a vehicle, there are many electronic devices called Electronic Control Units (ECUs), responsible for different functions like engine control, braking, air conditioning, and more.

The need for communication: These ECUs need to exchange information to ensure the vehicle runs smoothly and efficiently. For example, the engine control unit might need to inform the transmission control unit about the engine’s speed, so the transmission can shift gears at the right time.

The CAN bus: Instead of connecting each ECU to every other ECU with individual wires, which would be very complex and heavy, the CAN bus provides a simpler solution. It uses a single pair of wires, like a shared “highway,” on which all the ECUs can send and receive messages.

Message format: When an ECU wants to send information, it creates a message in a standard format. This message consists of an identifier (which indicates the data type being sent) and the actual data. The identifier ensures that each ECU knows which messages are relevant to it and can ignore the rest.

Transmitting messages: ECUs take turns sending messages on the CAN bus. If two ECUs try to send a message simultaneously, the one with the higher priority (lower numerical value of the identifier) goes first. This ensures that more critical information is sent without delay.

Receiving messages: When an ECU receives a message, it checks the identifier to determine its relevance. If so, it processes the data accordingly. If not, it simply ignores the message.

Error checking and fault tolerance: The CAN bus has built-in mechanisms to detect and correct errors in message transmission. The message can be retransmitted if an error is detected, ensuring reliable communication. Moreover, if one ECU or communication link fails, the other ECUs can continue functioning without any major impact on the overall system.

In summary, the CAN bus simplifies communication among electronic devices in a vehicle by using a shared “highway” for messages. This approach reduces wiring complexity, improves reliability, and allows for better control and diagnostics of vehicle systems.

Delving into the Detail – Understanding CAN bus message structure

Although this article is intended as a high-level view of CAN Bus technology, the following detail is useful in understanding CAN bus. Here we will look at the protocol and appreciate its benefits.

CAN bus messages, also known as frames, are structured to ensure efficient and reliable communication between devices on the network. A typical CAN bus message consists of several fields, including the identifier, data, and error-checking mechanisms. Here’s a detailed breakdown of these fields:

Start of Frame (SOF): The SOF is a single dominant bit that marks the beginning of a CAN bus message. It is used to synchronize the devices on the network.

Identifier (Arbitration Field): The identifier is an 11-bit field for standard CAN (CAN 2.0A) or a 29-bit field for extended CAN (CAN 2.0B). The identifier determines the message’s priority, with lower numerical values indicating higher priority. The identifier also specifies the message type, allowing devices to determine whether the message is relevant to them. Extended CAN has an 18-bit extension to the identifier field, and a single bit called the IDE (Identifier Extension) bit distinguishes between standard and extended frames.

Remote Transmission Request (RTR) bit: The RTR bit indicates whether the message is a regular data frame or a remote request frame. A dominant (0) RTR bit signifies a data frame, while a recessive (1) RTR bit signifies a remote request frame.

Data Length Code (DLC): The DLC is a 4-bit field specifying the number of data bytes in the message, ranging from 0 to 8. For CAN FD (Flexible Data Rate), the DLC can indicate up to 64 data bytes.

Data Field: The data field contains the actual payload of the message, which can be up to 8 bytes for standard CAN and up to 64 bytes for CAN FD. This field carries the information that devices on the network need to process.

Cyclic Redundancy Check (CRC): The CRC field is a 15-bit error-checking mechanism used to detect errors in the transmitted message. It is calculated based on the content of the message (identifier, RTR bit, DLC, and data field) and is transmitted as part of the message. The receiving devices also calculate the CRC based on the received data and compare it with the transmitted CRC to detect transmission errors.

CRC Delimiter: The CRC delimiter is a single recessive bit that separates the CRC field from the ACK field.

Acknowledge (ACK) bit: The ACK bit is a single bit used by the receiving devices to acknowledge the successful reception of a valid message. The transmitting device sends a recessive bit in the ACK slot, and any receiving device that successfully receives the message without errors overwrites the ACK bit with a dominant bit.

ACK Delimiter: The ACK delimiter is a single recessive bit that separates the ACK field from the end-of-frame field.

End of Frame (EOF): The EOF is a sequence of seven recessive bits that marks the end of a CAN bus message.

Interframe Space (IFS): The IFS is a minimum sequence of three recessive bits that separates consecutive messages on the CAN bus, providing a short pause for devices to prepare for the next message.

By understanding the structure of CAN bus messages, including the identifier, data, and error-checking mechanisms, we can appreciate the efficiency and reliability of this communication protocol. The combination of prioritization, error detection, and acknowledgement ensures that devices on the network can exchange information effectively and maintain the integrity of the data transmitted.

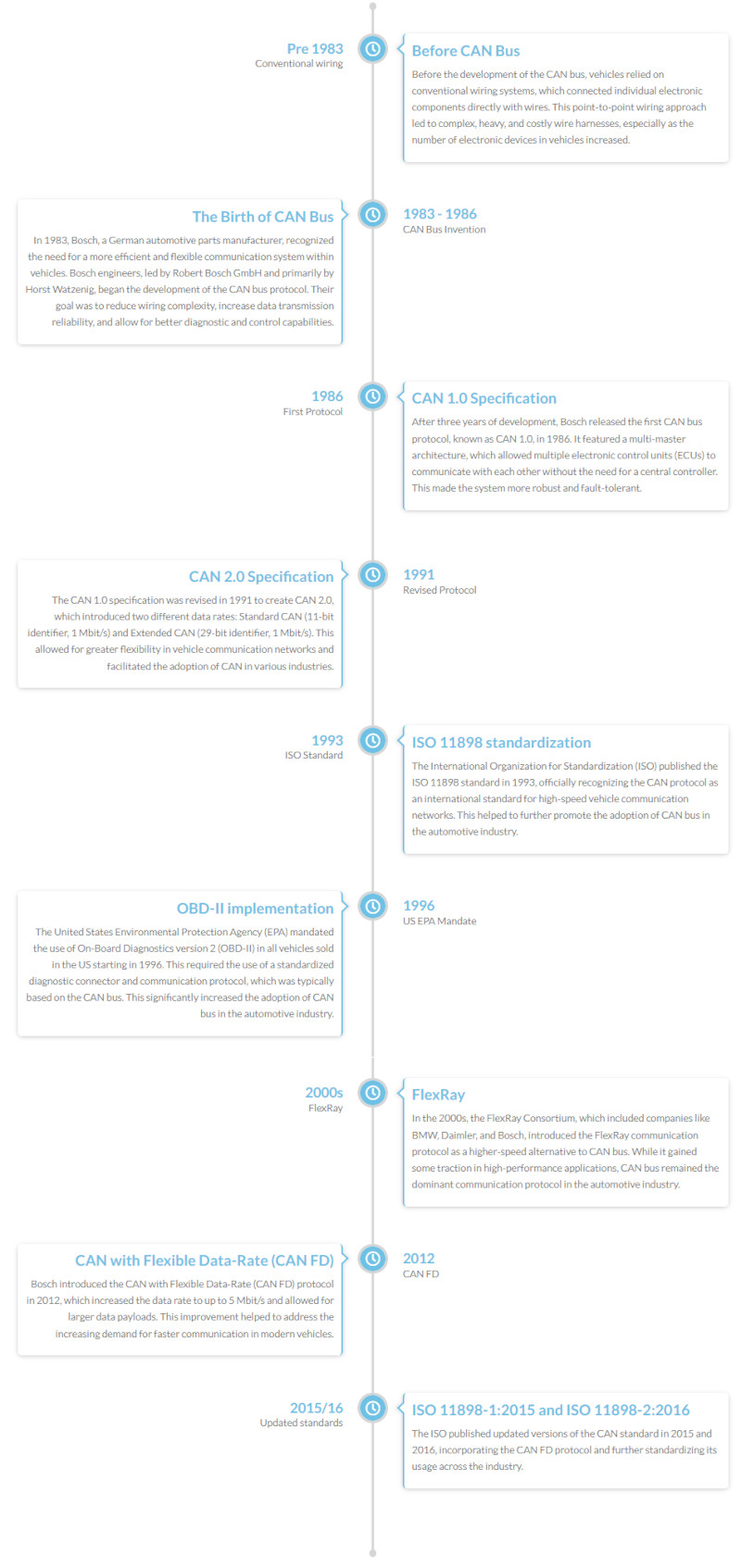

The History of CAN Bus

The development of the automotive Controller Area Network (CAN bus) is a fascinating story that reflects the automotive industry’s evolution in response to the increasing demand for electronics, communication, and control systems in vehicles. Let’s take a look at the key events and milestones in its history:

What are the Alternatives and Competitors to CAN bus

While the CAN bus has become the dominant communication protocol in the automotive industry, several alternatives and competitors have emerged to address specific requirements or limitations over the years. Some of the notable alternatives include:

LIN (Local Interconnect Network): LIN is a low-cost, single-wire serial communication protocol designed for less critical, lower-speed vehicle applications, such as door locks, window controls, and ambient lighting. With a lower data rate of up to 20 Kbit/s, LIN is often used in conjunction with CAN bus to create a hierarchical network architecture.

FlexRay: Developed by the FlexRay Consortium, FlexRay is a high-speed, deterministic communication protocol designed for safety-critical applications and advanced driver-assistance systems (ADAS). It offers data rates of up to 10 Mbit/s and supports both time-triggered and event-triggered communication. Although FlexRay offers advantages in performance and reliability, its complexity and cost have limited its adoption compared to CAN bus.

MOST (Media Oriented Systems Transport): MOST is a high-speed multimedia and infotainment network protocol designed specifically for automotive applications. It supports data rates of up to 150 Mbit/s and allows for transmitting audio, video, voice, and control data over a single optical fibre or electrical wire. While MOST is not a direct competitor to CAN bus, it is an alternative for multimedia applications where CAN bus may not be suitable.

Ethernet (BroadR-Reach, Automotive Ethernet): Automotive Ethernet is an adaptation of the widely used Ethernet protocol to meet the specific requirements of the automotive industry. It offers high-speed data transmission (up to 1 Gbit/s or higher) and supports advanced real-time communication features such as time-sensitive networking (TSN). Automotive Ethernet is increasingly being used in next-generation vehicles for high-bandwidth applications such as ADAS, infotainment, and vehicle-to-everything (V2X) communication.

TTCAN (Time-Triggered CAN): TTCAN is an extension of the CAN protocol that introduces time-triggered communication for real-time and safety-critical applications. It maintains compatibility with existing CAN networks while offering improved determinism and fault tolerance. TTCAN is used in niche applications and has not seen widespread adoption.

These alternatives and competitors to the CAN bus have emerged to address specific needs and requirements within the automotive industry. They often coexist with CAN Bus in modern vehicles, creating a heterogeneous network architecture that leverages the strengths of each communication protocol.

Understanding CAN Bus outside of the automotive industry?

Besides the automotive industry, the CAN bus has applications in various other industries due to its robustness, simplicity, and real-time communication capabilities. Some of these industries and applications include:

Industrial Automation: The CAN bus is used in factory automation systems, machine control, and robotics for communication between controllers, sensors, actuators, and other devices. It helps simplify wiring, reduces downtime, and enables real-time monitoring and control.

Agriculture: In modern agriculture, the CAN bus is used for communication between tractors, implements, and other agricultural machinery. This allows for better control, monitoring, and data sharing among equipment, improving efficiency and productivity.

Aerospace and Aviation: The CAN bus is used in some aircraft and spacecraft systems for communication between various subsystems and components, such as avionics, sensors, and actuators. It can provide a reliable and lightweight communication solution for complex aerospace systems.

Maritime and Offshore: The CAN bus is utilized in ships, offshore platforms, and other maritime applications to communicate between systems like engine management, navigation, and safety equipment.

Rail and Transportation: The CAN bus is employed in trains, trams, and other rail vehicles for communication between control systems, sensors, and other components. It can help streamline communication and improve the reliability of transportation systems.

Renewable Energy: In renewable energy systems, such as solar and wind farms, the CAN bus can communicate between inverters, charge controllers, sensors, and other components. This enables efficient monitoring, control, and data sharing across the energy system.

Medical Devices: The CAN bus is used in some medical equipment to communicate between devices, such as patient monitors, infusion pumps, and ventilators. It can provide a reliable and efficient communication solution for critical medical applications.

Building Automation: In building automation systems, the CAN bus can be used for communication between various building components like HVAC systems, lighting controls, and security systems, allowing for efficient control and monitoring of the building environment.

These examples demonstrate the versatility and reliability of the CAN bus as a communication solution across various industries and applications. Its ability to simplify wiring, provide real-time communication, and ensure fault tolerance makes it an attractive choice for many different scenarios.

Real World Examples of CAN Bus in use

Here are some real-world examples and case studies of how the CAN bus has been implemented in various vehicles, applications, and industries, including some unusual examples.

Automotive Industry:

Tesla Model S: The CAN bus is used extensively in Tesla’s electric vehicles, including the Model S. It enables communication between various subsystems such as the battery management system, powertrain, charging system, infotainment, and autopilot. The use of the CAN bus simplifies wiring, reduces weight, and enables real-time monitoring and control of these subsystems, contributing to the vehicle’s overall efficiency, safety, and performance.

Formula 1 Racing Cars: In the high-stakes world of Formula 1 racing, the CAN bus is employed to communicate between various critical systems like engine management, transmission, brakes, suspension, and telemetry. The high-speed, real-time communication provided by the CAN bus allows engineers to monitor and optimize the performance of the racing cars during races and testing.

Outside the Automotive Industry:

Industrial Automation: The CAN bus is used in factory automation systems, such as conveyor belts and robotic arms, to communicate between controllers, sensors, and actuators. Implementing the CAN bus in these systems simplifies wiring, reduces downtime due to faults, and enables real-time control and monitoring. In a case study by Festo, a leading automation technology provider, they utilized the CAN bus to interconnect a production system’s components, improving both the flexibility and scalability of the system.

Agriculture: A John Deere case study showcased how the company implemented the CAN bus in their large tractors, enabling better communication between the tractor and implements. This improved system allowed farmers to monitor and adjust equipment settings in real-time, increasing productivity and efficiency.

Unusual Non-Automotive Examples:

Art Installations: In a unique application, the artist Julius Popp used the CAN bus to create an interactive art installation called “bit.code.” The installation featured a large wall of moving flip-dots that displayed words and patterns based on data from the internet. The CAN bus was employed to control and synchronize the movement of the flip-dots, enabling the artist to create a dynamic and engaging visual experience.

Amusement Park Rides: The CAN bus has been implemented in amusement park rides, such as roller coasters and simulators, for communication between control systems, sensors, and actuators. A case study from KUKA, a leading manufacturer of industrial robots and automation technology, described how they used the CAN bus to control and monitor the “Robocoaster,” a robotic arm-based thrill ride. The CAN bus allowed for precise control, real-time monitoring, and improved ride safety.

These examples illustrate the versatility and reliability of the CAN bus in various industries and applications, both automotive and non-automotive. Using the CAN bus can significantly improve efficiency, safety, and performance, making it a valuable communication solution for a wide range of scenarios.

CAN Bus – The Future

As technology advances, the CAN bus and vehicle communication networks are expected to evolve to meet the growing demands of modern vehicles. Here are some upcoming trends and technologies that could shape the future of vehicle communication networks:

CAN FD (Flexible Data Rate): CAN FD is an extension of the traditional CAN bus protocol, which allows for higher data rates (up to 5 Mbps) and larger payload sizes (up to 64 bytes). This enhanced capability can better accommodate the increasing data demands of modern vehicles, such as advanced driver assistance systems (ADAS) and electric powertrains. As more vehicles incorporate these complex systems, we can expect CAN FD adoption to grow in the coming years.

Time-Sensitive Networking (TSN): TSN is a set of IEEE standards aimed at improving the determinism and latency of Ethernet networks. Manufacturers can achieve more precise synchronization and real-time communication between devices by incorporating TSN capabilities into vehicle communication networks. This technology could become increasingly important as autonomous driving systems and other safety-critical applications become more prevalent in the automotive industry.

Vehicle-to-Everything (V2X) Communication: V2X communication encompasses vehicle-to-vehicle (V2V), vehicle-to-infrastructure (V2I), vehicle-to-pedestrian (V2P), and vehicle-to-network (V2N) communication. These technologies enable vehicles to share information with other vehicles, infrastructure, and devices in their environment, improving traffic efficiency, safety, and enabling new services. As V2X communication becomes more widespread, the CAN bus and other in-vehicle networks must adapt and integrate with these external communication systems.

Cybersecurity: With the increasing connectivity of modern vehicles, cybersecurity has become a critical concern in the automotive industry. As a result, there is a growing focus on implementing secure communication protocols and encryption methods within the CAN bus and other vehicle communication networks to protect against unauthorized access and potential attacks.

Integration of Advanced Driver Assistance Systems (ADAS) and Autonomous Driving: As ADAS and autonomous driving technologies continue to develop, the demand for high-speed, reliable, and secure communication networks will increase. The CAN bus and other vehicle communication networks must evolve to support the complex sensor data, control signals, and real-time decision-making required for these systems to function effectively.

Multi-Gigabit Automotive Ethernet: Automotive Ethernet is a growing trend in vehicle communication networks, providing high-speed data transfer rates and the ability to support multiple protocols. As the demand for data-intensive applications like ADAS, infotainment, and electrification grows, multi-gigabit automotive Ethernet could play an increasingly important role in supplementing or replacing traditional CAN bus networks in some applications.

These trends and technologies illustrate the potential future of vehicle communication networks as the CAN bus and other protocols evolve to meet the demands of increasingly complex and connected vehicles. The focus on enhanced data rates, real-time communication, cybersecurity, and integration with emerging vehicle technologies will shape the development of vehicle communication networks in the coming years.

Conclusion

This is a broad, high-level view of CAN bus and the associated technologies. If you want to learn more about how CAN bus logging can be closely integrated with noise & vibration measurement and other testing tasks, please look at the DATS-CANetic system on the Prosig website.

Chris Mason

Latest posts by Chris Mason (see all)

- Rotating Machinery Vibration Analysis: Keeping Your Machines Humming Along - November 27, 2023

- Vibration Control and Isolation: A Comprehensive Guide for Engineers - November 6, 2023

- Modal Analysis in the Real World - October 6, 2023