The following application note describes the test and measurement process for the fatigue & durability testing and development cycle of an automotive suspension component, specifically a tie rod. The component had been known to fail at various intervals. An estimate of the predicted fatigue life of the component was required in order to assess the feasibility of its continued use and to see if a design change was required. The component under test is shown in Figure 1. The testing was carried out by a major automotive manufacturer. Strain gauges were used to monitor the strain levels.

First, the vehicle was instrumented and data acquired whilst the vehicle was on a test track. The vehicle under test was then mounted on a four-post shaker rig that simulates actual road conditions. Particular sections of the actual test run from the test track could be replicated for much longer periods than otherwise would be possible, additionally this could all be done in the controlled conditions of the test laboratory.

This article will focus on the capture of the strain data and the processing of such data using ‘Stress Life’ and ‘Fatigue Life Prediction’ methods to predict the expected life of the component.

Initially the vehicle was instrumented with strain gauges using a Prosig P8000 portable data acquisition system. The vehicle was driven around a test track and data from the strain gauges acquired with the P8000 data acquisition unit. The data capture and signal processing procedure can be seen and followed from start to finish.

Figure 2 shows an example of a strain gauge attached to the component under test by adhesive. In this case the gauge is a two wire device.

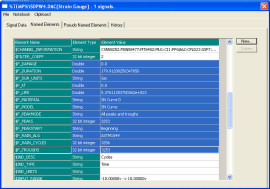

After launching the Prosig Data Acquisition software various setup fields must be filled in such as signal names, signal types and so on. To assist clarity in this application note only one strain gauge is being used and it is operating in a quarter bridge completion configuration. It is a 120 Ohm gauge and an excitation of 10VDC has been selected to be applied as shown in Figure 3.

Next the Prosig P8000 and associated acquisition software are used to capture the strain data from the vehicle as it driven around the test track. The real time display, Figure 4, shows the micro strain and the oscillatory nature of the data as it is being captured.

On completion of the data capture stage, the next step was to return to the testing laboratory and use the vehicle shaker test rig. The DATS signal processing software was used to identify significant frequencies and amplitudes of strain data that the vehicle had been subject to on the test track. The analogue output facilityof the P8000 was then used to ‘replay’ the signals into the shaker to ‘mimic’ particular sections of the track. This allowed the test engineers to control the amount of time the component under test was subjected to specific frequencies or amplitudes. During any one hour period on the test track the component might be subjected to a particular excitation pattern for only a few seconds. But, by capturing the data while the vehicle is moving on the track and then using the shaker rig, it is possible to subject the component to a period of accelerated saturation testing of particular frequencies and amplitude characteristics.

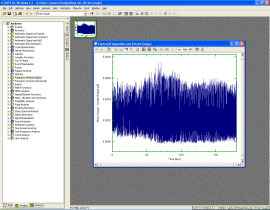

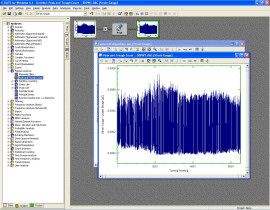

For this application note the suspension component was excited for 180 seconds. The excitation was captured with the P8000 and opened in the DATS signal processing software (Figure 5). At this stage the strain data is stored and displayed with respect to time. The degree of micro strain that the component was subjected to can be seen over the entire capture period.

In order to begin the fatigue life prediction it is first necessary to analyze the peak and trough content of the captured data. This is easily achieved using the DATS Fatigue Life Analysis software tool kit.

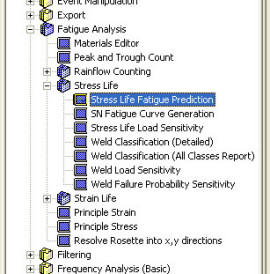

The peak and trough data shown in Figure 6 was produced by selecting the relevant analysis module as highlighted in Figure 7.

Next, it was required to generate an S-N curve for the component as depicted in Figures 7 and 8. It is important to note that this is not an S-N curve for the material used in fabricating the component, but the S-N curve for the component itself.

At this stage limited data is available for predicting failure rates and moreover this information is rough and sporadic. This, however, will not be used to produce the S-N curve at this point. The failure data will be used later to refine the S-N curve.

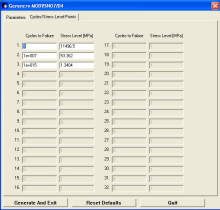

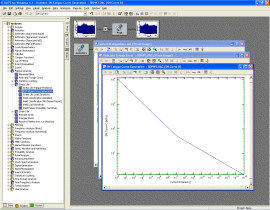

Using the DATS Fatigue Life Analysis module for S-N curve generation (Figures 9 & 10) it is possible to produce an S-N curve.

S-N curves are by their nature very simple, they can usually be approximated by two intersecting straight lines on a graph of log stress verses log cycles. In this case three points are used to create the curve.

A set number of cycles to failure and stress levels are required. As mentioned previously the S-N curve will be refined later. At this stage, the values for the ‘Weld Classification’ are used. These are chosen arbitrarily as it is a known curve that closely follows that of the material under test. The generated S-N curve is then created as shown in Figure 11.

With the peak trough data and S-N curve it is possible to complete a fatigue life prediction, using the ‘Stress Life Fatigue Prediction’ analysis module (Figure 12). To complete this analysis both the S-N curve and the initial peak and trough data are required.

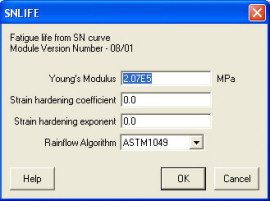

When the analysis module begins it prompts the user for certain values (Figure 13).

The fatigue life prediction analysis module requires a Young’s modulus for the material, in this case 2.07×104 MPa. A rain flow algorithm must also be selected, in this case the ASTM1094. (American Society for Testing and Materials, Revision 1985).

The conversion from Micro Strain to Stress uses the following formula. The micro strain values, $\epsilon$, are translated into stress, S, by solving

Where

E is Young’s Modulus

K’ is Strain Hardening Coefficient

n’ is Strain Hardening Exponent

If K’ or n’ or both are zero then the module uses

This analysis takes two input datasets: the peak and trough count and the S-N curve. The resultant ‘Stress Life Fatigue Prediction’ damage curve is shown in Figure 14, with a fatigue life prediction of 5.36×1023 seconds.

The Fatigue Life Prediction analysis also calculates more detailed results stored as Named Elements. These are shown highlighted in blue in Figure 15. They include Damage, Duration of original time sample, Number of cycles and so on.

To summarize thus far, it has been possible to complete a fatigue life prediction from a sample of strain data taken over a specific time period.

This has given a predicted life of 5.36×1023 seconds.

As discussed earlier, the S-N curve was not a refined curve and was almost arbitrary in its construction. This could potentially lead to errors. Therefore at this stage the S-N curve must be refined to allow recalculation of more accurate results and thus remove any potential errors.

The component in question has been reported to fail in the field after various time periods, hence the reason for the trial. Although the stress and strain levels are not known for these failures the time to failure is important. Because it is possible to apply the expected strain level for general use to the component for the known period of time, it is, therefore, possible to extrapolate the stress levels. Note, the stress levels and cycles to failure are not known for these situations. Only the time to failure is known.

The automotive component was also tested to failure, with failures occurring at the following intervals. As these failures were under controlled test environments they can be considered to be more accurate than the predicition result discussed previously. These have times to failures of:

Time to failure 6.48×105 seconds with a stress of 0.003010 MPa

Time to failure 6.75×107 seconds with a stress of 0.000165 MPa

The following have known times to failure, but with unknown strain levels. For these cases the known failure stress levels can be used, in this case 0.000165 MPa is chosen.

1.52×107 seconds

7.78×107 seconds

2.64×106 seconds

The cycles of the vehicle suspension component, importantly not the cycles of material, were at 2Hz. However, the material cycles were, from the peak and trough calculations in the captured data 3253 in a 180 second snap shot.

Therefore, it is possible to calculate the number of material cycles for the known failure times and then to accurately adjust our initial S-N curve.

It is also possible to calculate cycles to failure for the situations where the known failure times do not have strain information. This can be achieved because it is possible from experimental testing to deduce what the expected or average use and therefore strains will be.

| Known or unknown strain | Time to failure (seconds) | Cycles per 180 seconds | Cycles to failure (seconds) |

|---|---|---|---|

| Known | 6.48x105 | 3253 | 11710800 |

| Known | 6.75x107 | 3253 | 1219875000 |

| Unknown | 1.52x107 | 3253 | 274697777 |

| Unknown | 7.78x107 | 3253 | 1406018888 |

| Unknown | 2.64x106 | 3253 | 47710666 |

It is now possible to refine the original S-N curve (Figure 16) with the 5 pairs of values calculated,

0.003010 MPa and 11710800 cycles to failure

0.000165 MPa and 1219875000 cycles to failure

0.000165 MPa and 274697777 cycles to failure

0.000165 MPa and 1406018888 cycles to failure

0.000165 MPa and 47710666 cycles to failure

Therefore it is possible to extrapolate what the S-N curve could have been and thus re-process the results using the automatic reprocessing features of DATS as shown in Figure 16.

The result of the re-processed fatigue life prediction is 21.3×106 seconds.

The conclusion is that after approximately 246 days of use at the expected level of 10 hours use per day this component could be expected to fail. Clearly this is a fragile component that is likely to fail in an unacceptably short amount of time for an automotive application and both a technical design change and further testing are required.

It is evident that the more testing to failure that is carried out the more accurate the final life prediction will be.

[Note: This article has been reduced in complexity compared with the original tests and uses deliberately modified initial strain values]

James Wren

Latest posts by James Wren (see all)

- What Are dB, Noise Floor & Dynamic Range? - January 12, 2024

- How Do I Upsample and Downsample My Data? - January 27, 2017

- What Are Vibration, Torsional Vibration & Shaft Twist? - November 8, 2016

Hello,

What adhesive did you use?

Many thanks,

Darren

Hello Mr Cox, thanks for asking the question.

You have to use certain adhesive for certain applications, high temperature or low temperature for example, but also for low or high strain levels.

But generally we would use something like an Cyanoacrylate Adhesive.

This sort of adhesive will normally be sold with the strain gauges by the manufacturers, with the particular application in mind.

I am interested in the equipment Prosig P8000 portable data acquisition system and Data Acquisition Prosig software , because it is useful for my research on the mechanical behavior of composite materials due to high strain rate impact loading. Therefore, I want to get your best price offer and the steps the installation of equipment. Thank you for your cooperation.

Hello Zulfikar,

We will contact you directly, but please feel free to use the Prosig Quotation Request form to make a formal enquiry.

Hello James,

May I get some idea about the cost about the fatigue life calculation module on top of our current hardware and software, as well as the maintainance contracts? Thanks.

Hello Mr Yao,

I will speak with you when I next visit your factory, but in the meantime please feel free to use the Prosig Quotation Request form to make a formal enquiry.

I know that it is not really related to the article above. But, I need to ask what is the importance of the vibration testing process for the machine?

Hello Graham,

Thank you for asking a question on our blog.

You are asking a complex question, this article relates to fatigue measurement, the calculation of fatigue comes from strain gauges. There have been studies to compare and relate strain to acceleration, but it is a complex relationship and a large amount of testing has to be completed, a large amount even in terms of fatigue testing which has itself a large requirement for data capture.

So to answer your question, there is a relationship, but a tentative and complex one at that.

If you would like to discuss this subject further please feel free contact us directly.

Hi James,

I have a project which is to detect fatigue stress and fatigue crack growth in our plant. Is it possible to invite you as the expert. Please provide your contact detail asap.

Hello Mr Kadir,

We would be happy to assist you further, please feel free to contact us directly at sales@prosig.com then we can discuss your requirements with you directly.

I work for wheel rim manufacturer and my responsible in R&D department.

i am interested in the equipment of strain gauge to evaluate actual strain of wheel disc during fatigue test perform.I want to get your estimation price and please advice me suitable type of strain gauge.

Hello Mr Pipin,

Thank you for posting on our blog.

I have sent you an email to begin discussion of your requirements directly.

Thank you for this useful blog

Glad to help! Please feel free to ask if you have any questions at all.