Aliasing, Orders and Wagon Wheels

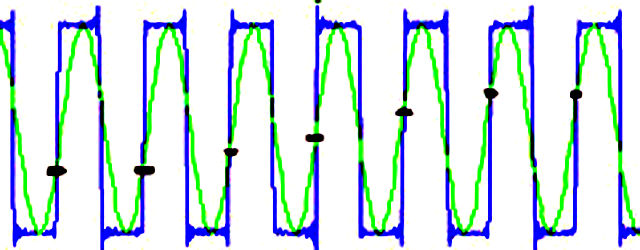

These days most people collecting engineering and scientific data digitally have heard of and know of the implications of the sample rate and the highest observable frequency in order to avoid aliasing. For those people who are perhaps unfamiliar with the phenomenon of aliasing then an Appendix is included below which illustrates the phenomenon.

In saying that most people are aware of the relationship concerning sample rate and aliasing this generally means they are aware of it when dealing with constant time step sampling where digital values are measured at equal increments of time. There is far less familiarity with the relevant relationship when dealing with orders, where an order is a multiple of the rotational rate of the shaft. For example second order is a rate that is exactly twice the current rotational speed of the shaft. What we are considering here then is the relationship between the rate at which we collect data from a rotating shaft and the highest order to avoid aliasing.

The relationship depends on how we do our sampling as we could sample at constant time steps (equi-time step sampling), or at equal angles spaced around the shaft (equi-angular or synchronous sampling). We will consider both of these but first let us recall the relationship for regular equi-time step sampling and the highest frequency permissible to avoid aliasing. This is often known as Shannons Theorem [Learn more about Claude E Shannon].

(more…)

Ever been lying on the beach and begun to wonder about the state of your LP turbines? Or out on business and anxious to know if that troublesome exciter bearing has settled down? Well with a

Ever been lying on the beach and begun to wonder about the state of your LP turbines? Or out on business and anxious to know if that troublesome exciter bearing has settled down? Well with a

Knowing how to measure torsional vibration is of key importance in the area of vehicle development and refinement. The main contributory source is the engine where periodically occurring combustion cycles cause variation in the crankshaft rotary vibration. This vibration is transmitted to and modified further by other components in the powertrain such as the gearbox and by other equipment driven off the drive belt or chain. Additional torsional vibrations are also likely to appear downstream at the drive shafts and wheels.

Knowing how to measure torsional vibration is of key importance in the area of vehicle development and refinement. The main contributory source is the engine where periodically occurring combustion cycles cause variation in the crankshaft rotary vibration. This vibration is transmitted to and modified further by other components in the powertrain such as the gearbox and by other equipment driven off the drive belt or chain. Additional torsional vibrations are also likely to appear downstream at the drive shafts and wheels.

Prosig

Prosig